About Our Fabrication Shop

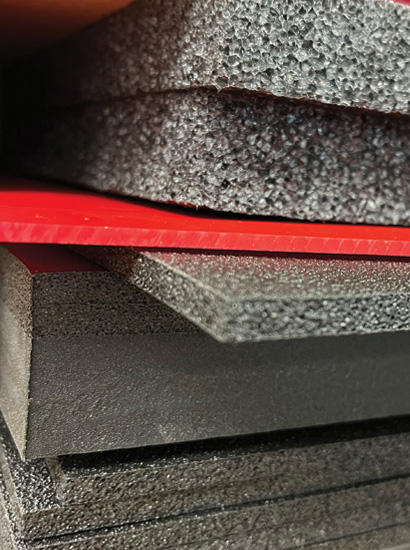

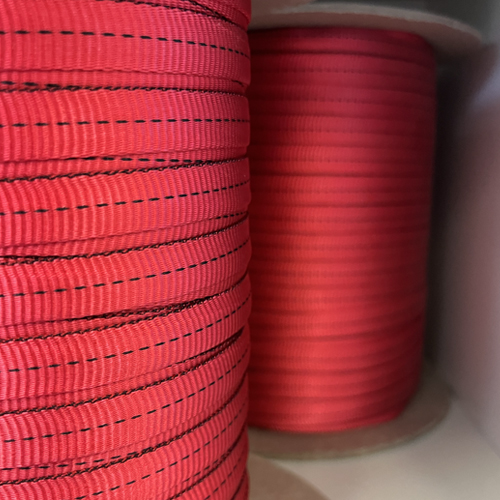

Our in-house Fabrication Shop is equipped to deliver precision-engineered solutions across a range of mission-critical materials & use cases. We offer advanced custom foam cutting, laser etching, & CNC machining, with two-axis CNC systems capable of processing foam, wood, textiles, plastics, & acrylics with exacting accuracy. Our industrial-grade laser engraving systems are built to meet the identification & compliance needs of government sectors, with the ability to etch on steel, aluminum, anodized & coated metals, & polycarbonate plastics. Whether for protective packaging, part marking, or custom structural components, our fabrication team delivers scalable, high-tolerance results built for field readiness & operational performance.